There’s little more disruptive than the persistent whine or grind of a struggling electric fan. What once provided a soothing breeze or essential airflow can quickly become an irritating distraction. If your trusty fan isn’t quite living up to its name, sounding more like a tired machine than a refreshing companion, the solution might be simpler (and cheaper) than you think: lubrication. Just like any moving mechanical part, the bearings within your electric fan require proper care to ensure smooth, efficient, and silent operation. This comprehensive guide will walk you through everything you need to know to bring your fan back to life.

Why Lubricate Fan Bearings?

Understanding why lubrication is crucial for your electric fan begins with recognizing the signs of neglect. When bearings run dry, friction increases, leading to a cascade of problems that affect performance and lifespan.

Signs Your Fan Needs Lubrication

Listen closely to your fan; it often tells you when something is amiss.

- Unusual Noises: The most common indicator. Grinding, squeaking, buzzing, or clicking sounds are clear signals that the bearings lack sufficient lubrication and metal is rubbing against metal.

- Reduced Speed: If your fan seems to spin slower than usual or struggles to reach its highest speed settings, increased friction within the bearings could be the culprit, impeding the motor’s ability to turn the blades freely.

- Vibrations or Wobbling: Excessive friction can lead to uneven rotation, causing the fan blades or motor assembly to vibrate uncomfortably. This isn’t just annoying; it can accelerate wear on other components.

- Overheating Motor: When friction is high, the motor has to work harder, generating more heat. An unusually hot motor indicates significant internal resistance, often stemming from dry bearings. Catching this early can prevent permanent motor damage.

Benefits of Proper Lubrication

Taking the time to lubricate your fan’s bearings offers substantial rewards.

- Extended Lifespan: Regular lubrication drastically reduces wear and tear on crucial moving parts, helping your fan last years longer than an unmaintained one.

- Quiet Operation: By minimizing friction, lubrication eliminates those annoying noises, allowing your fan to return to its intended whisper-quiet (or at least much quieter) performance.

- Improved Efficiency: A well-lubricated fan requires less energy to operate at its optimal speed, potentially leading to slight energy savings and consistent airflow.

- Consistent Airflow: Smooth-spinning blades ensure steady and powerful air movement, providing the cooling or ventilation you rely on.

Understanding Fan Bearing Types

Before you dive into lubrication, it helps to know a little about the types of bearings commonly found in electric fans. The two most prevalent are sleeve bearings and ball bearings, each with different maintenance considerations.

Sleeve Bearings

Sleeve bearings, also known as plain or bushing bearings, are simple, cost-effective components often found in many common household fans. They consist of a soft metal (like bronze or brass) sleeve that surrounds the fan shaft. These bearings rely on a thin film of lubricant to operate smoothly. Over time, this lubricant can dry out or evaporate, leading to increased friction and noise. Sleeve bearings are typically the most responsive to lubrication, as they are designed to be re-oiled.

Ball Bearings

Ball bearings use a series of small, hardened steel balls housed between two rings (races) to reduce friction. They offer greater durability and are often found in higher-quality or industrial fans designed for continuous operation. Many ball bearings are “sealed” or “pre-lubricated,” meaning they are not intended for user maintenance. Attempting to force lubricant into sealed ball bearings can sometimes do more harm than good. However, some older or larger ball-bearing fans might have accessible lubrication ports. Always consult your fan’s manual if available. If a ball bearing fan becomes noisy and is sealed, it often indicates the bearing has failed and requires replacement, rather than lubrication.

Choosing the Right Lubricant for Your Electric Fan

Selecting the correct lubricant is paramount. Using the wrong type can cause more damage than good, attracting dust, degrading plastic components, or failing to provide lasting lubrication.

Recommended Lubricants

For most electric fan bearings, especially sleeve bearings, light machine oil is the go-to choice.

- Sewing Machine Oil: This is perhaps the most widely recommended and readily available option. It’s a light, non-detergent oil that provides excellent lubrication without gumming up or attracting excessive dust. Brands like Singer sewing machine oil are often cited.

- Light Machine Oil: Similar to sewing machine oil, this is a general-purpose lubricant designed for precision mechanisms. Look for non-detergent varieties specifically labeled for electric motors or general machine use.

- Zoom Spout Turbine Oil: Many experts recommend specific turbine oils, especially those in the “Zoom Spout” brand, which are formulated for electric motors and HVAC systems. These are typically non-detergent and have an ideal viscosity.

- Non-Detergent Motor Oil (SAE 15 or 20wt): If you can find a non-detergent motor oil, a light weight (like SAE 15 or 20) can work well for larger fan motors, particularly in industrial or older residential fans. Crucially, ensure it’s non-detergent, as detergents can break down existing lubricants and become sticky.

- Specific Electronic Equipment Oil: For smaller computer or electronic fans, specialized electronic oils or “lube oils” designed for small motors are excellent choices.

Lubricants to Avoid

Just as important as knowing what to use, is knowing what to avoid.

- WD-40: Despite its popularity, WD-40 is primarily a water displacement and rust-preventative spray, not a long-term lubricant. It evaporates quickly, leaving behind a thin film that can actually attract dust and exacerbate friction over time.

- Detergent Motor Oils: Most automotive engine oils contain detergents designed to clean engine internals. These detergents are detrimental to the delicate bearings of electric fans, potentially causing buildup and premature failure.

- Thick Greases (unless specified): While some heavier industrial fans might use grease, for typical household and computer fans, thick greases can impede movement and attract dirt, leading to more problems. Silicone or lithium greases are sometimes mentioned for plastic moving parts, but oil is generally preferred for metal bearings.

“For optimal fan bearing health, always reach for a light, non-detergent machine oil. Think sewing machine oil, not your car’s engine oil. The wrong lubricant can turn a simple fix into a sticky, dust-collecting mess.” – Dr. Elena Petrova, Mechanical Engineering Specialist

Tools and Materials You’ll Need

Gathering your tools before you start will make the process much smoother and ensure you have everything on hand.

- Screwdrivers (Phillips and Flathead): For disassembling fan guards, motor housings, and sometimes fan blades.

- Soft Brush or Compressed Air: Essential for removing dust and debris from fan blades, grilles, and especially around the motor and bearings.

- Clean Rags or Paper Towels: For wiping away excess oil and cleaning components.

- Cotton Swabs or Toothpicks: Useful for precise cleaning and applying small drops of oil in tight spaces.

- The Chosen Lubricant: As discussed, a high-quality light machine oil.

- Small Applicator Bottle (optional): A needle-tip oiler can make applying drops much easier and more precise.

- Gloves (optional): To keep your hands clean.

Step-by-Step Guide: How to Lubricate Fan Bearings

Now, let’s get hands-on. Remember that specific disassembly steps may vary slightly depending on your fan type, but the core lubrication principles remain consistent.

1. Safety First: Disconnect Power

Before touching anything, ensure the fan is completely powered off and unplugged from the wall socket. For ceiling fans or central air units, turn off the power at the breaker switch to prevent any accidental activation. This is a non-negotiable safety step.

2. Disassemble the Fan

Carefully begin disassembling your fan.

- For Desk/Pedestal Fans: Remove the front grille, then the nut or cap holding the fan blade in place. Slide the blade off. You might then need to remove screws to access the motor housing.

- For Ceiling Fans: If your ceiling fan has oil ports, you might not need extensive disassembly. Otherwise, you’ll need to remove the fan blades and potentially the motor housing cover to access the bearings. Always follow your manufacturer’s instructions.

- For Computer Fans: Often, you can peel back a sticker on the back of the fan to reveal the bearing access point. In some cases, you might need to gently pry off the fan blades from the central shaft.

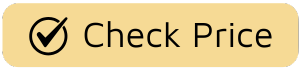

A person carefully disassembling an electric fan, cleaning dust from blades and grille with a soft brush, prior to lubrication.

A person carefully disassembling an electric fan, cleaning dust from blades and grille with a soft brush, prior to lubrication.

3. Clean the Fan Components

Dust and grime are the enemies of smooth operation.

- Thoroughly clean the fan blades, grilles, and any accessible parts with a soft brush or a damp cloth.

- Use compressed air to blow out dust from inside the motor housing and around the bearing areas.

- For particularly stubborn grime, cotton swabs can be effective in tight spots. Ensure all dust and debris are removed before applying oil.

4. Locate the Bearings/Lubrication Ports

This is the critical step for applying lubricant.

- Sleeve Bearings: You’ll typically find the bearings where the fan shaft enters the motor housing. Older fans might have small, visible oil ports or holes near the shaft. Newer models may require you to peel back a sticker or remove a small rubber cap on the back of the motor to expose the bearing well.

- Ball Bearings (if accessible): Some ball bearing fans might have specific oil ports. If they are sealed and no ports are visible, they are likely not designed for user lubrication. Do not attempt to force entry.

5. Apply the Lubricant

Once the bearing location is identified and cleaned, it’s time to lubricate.

- Using your chosen lubricant and a small applicator (or directly from the bottle, if it has a fine nozzle), apply just a few drops of oil directly onto the bearing or into the oil port. The goal is to allow the oil to seep into the bearing mechanism.

- Spin the Fan: Gently spin the fan blades by hand several times to help distribute the oil evenly within the bearing.

- Allow to Soak: Let the oil sit for a few minutes to penetrate fully. You can repeat the application of a drop or two, spinning the fan each time, until you feel the shaft moving more freely and quietly. Avoid over-oiling, as excess can leak out and attract more dust.

- Wipe Excess: Use a clean rag or cotton swab to wipe away any excess oil from the exterior of the bearing and surrounding components.

A close-up of a hand applying a few drops of lubricating oil to an electric fan bearing with a precision applicator for smooth operation.

A close-up of a hand applying a few drops of lubricating oil to an electric fan bearing with a precision applicator for smooth operation.

6. Reassemble and Test

Carefully reverse the disassembly steps to put your fan back together.

- Ensure all screws are tightened, and guards are securely in place.

- Once fully reassembled, plug the fan back in and turn it on.

- Listen for any lingering noises and observe the fan’s speed and stability. Ideally, it should run much more quietly and smoothly.

Specific Lubrication Tips for Different Fan Types

While the general steps are similar, certain fan types have unique considerations.

Desk and Pedestal Fans

These are often the easiest to lubricate. Their motors are usually enclosed in a plastic housing that can be opened with a few screws. The bearings are typically sleeve bearings located on the motor shaft at both the front and rear of the motor. You might need to remove the fan blades and the front motor cover to access the front bearing, and potentially the back cover for the rear bearing.

Ceiling Fans

Many older ceiling fans are designed with easily accessible oil fill holes on the motor housing, often near the top. These holes might be covered by a rubber plug or a small screw. Use a light machine oil and fill until it just starts to trickle out. Newer models, especially those with sealed ball bearings, may not have these ports and are generally not user-serviceable for lubrication. Always check the owner’s manual for specific instructions.

Computer and Electronics Fans

These fans are smaller and more delicate. Most small DC fans use sleeve bearings. You’ll typically find a sticker on the back of the fan hub. Carefully peel this back to reveal a small rubber or plastic cap, or sometimes the bearing opening directly. Gently remove the cap (if present) to expose the bearing. Apply only one or two tiny drops of very light machine oil or electronic-specific lubricant. Rotate the fan gently, then replace the cap and sticker. Be extremely careful not to over-oil, as excess lubricant can interfere with sensitive electronic components.

Frequency of Lubrication

How often should you lubricate your electric fan bearings? There’s no single answer, as it depends on usage and environment.

- Listen to Your Fan: The best indicator is always the fan itself. If it starts making noise, it’s time for lubrication.

- Heavy Use: For fans used daily for many hours, consider lubricating every 6-12 months.

- Intermittent Use: For fans used seasonally or occasionally, an annual check-up and lubrication might suffice.

- Dusty Environments: Fans operating in dusty environments might need more frequent cleaning and lubrication, as dust can contaminate the lubricant and accelerate wear.

Troubleshooting Common Issues After Lubrication

Sometimes, even after careful lubrication, a fan might not perform as expected.

Still Noisy or Vibrating

- Worn Bearings: If the fan still makes noise or has excessive wobbling after lubrication, the bearings might be severely worn out. If you can wiggle the fan shaft side-to-side (not just in-and-out play, which is normal for some sleeve bearings), the bearings are likely beyond repair and require replacement. For many fans, this means replacing the entire motor assembly.

- Insufficient Lubrication: Ensure the oil has fully penetrated the bearing. Sometimes, old, solidified lubricant needs to be flushed out (using a small amount of rubbing alcohol or brake cleaner, carefully, then re-oiling) before new oil can be effective.

- Other Issues: The noise might not be from the bearings. Check for loose fan blades, imbalanced blades, or debris caught in the motor housing.

Fan Not Spinning

- Reassembly Error: Double-check that all wiring (if applicable) is correctly connected and no components are binding. Ensure the fan blades are securely attached and not rubbing against the guard.

- Motor Failure: In some cases, the motor itself may have failed, especially if it was allowed to run dry and overheat for an extended period. At this point, replacement is usually the only option.

Conclusion

A little maintenance goes a long way in preserving the life and performance of your electric fan. Taking the time to properly lubricate its bearings can transform a noisy, inefficient appliance back into a quiet, reliable source of comfort. By understanding the types of lubricants to use, the steps involved, and the specific needs of different fan models, you empower yourself to extend your fan’s lifespan and enjoy peaceful, continuous airflow. Don’t let a squeak turn into a costly replacement; give your electric fan the care it deserves, and it will continue to keep you cool for years to come.

Frequently Asked Questions

Can I use cooking oil to lubricate fan bearings?

No, you should not use cooking oil. Cooking oils are not designed for mechanical lubrication, can quickly become sticky, attract dust, and eventually go rancid, causing more damage and odors to your fan. Always use a dedicated light machine oil.

How do I know if my fan has sealed bearings?

Fans with sealed bearings typically won’t have any visible oil ports, rubber caps, or removable stickers on the motor housing explicitly for lubrication. If your fan manual doesn’t mention lubrication, it likely has sealed bearings that are not user-serviceable.

What happens if I over-lubricate my fan bearings?

Over-lubrication can lead to excess oil leaking out, which can attract more dust and dirt to the motor and other components, potentially creating a sticky mess and even short-circuiting electrical parts if the oil reaches them. Always use just a few drops and wipe away any excess.

Is it necessary to lubricate new fans?

Generally, new fans come adequately lubricated from the factory. Lubrication is typically part of preventative maintenance for older fans or those showing signs of wear and noise. However, some enthusiasts might pre-lube new sleeve bearing computer fans for extended life.

My fan is still noisy after lubrication, what should I do?

If your fan remains noisy after proper lubrication, the bearings might be severely worn or damaged beyond repair. At this point, lubrication will only offer a temporary fix, if any. You might need to consider replacing the fan motor or the entire fan unit. Check for excessive side-to-side play in the shaft, which is a strong indicator of terminal bearing wear.